When you choose UV-cured urethane for your flooring or furniture, you’re investing in a finish that stands up to daily wear and tear better than many traditional coatings. It offers stronger scratch resistance, excellent protection against spills and stains, and keeps colors vibrant longer. Plus, the factory-applied process ensures consistent quality, while the quick curing saves time. But there’s more to why it’s becoming a preferred choice in both homes and commercial spaces.

Key Takeaways

- UV-cured urethane provides superior durability and scratch resistance, keeping surfaces looking new longer.

- It offers excellent protection against spills and stains, preventing permanent damage.

- The finish resists fading by blocking UV rays, preserving vibrant colors over time.

- Factory application ensures consistent quality with even, multi-layer coatings for maximum protection.

- The UV curing process is environmentally friendly, using less energy and reducing harmful emissions.

Enhanced Durability and Scratch Resistance

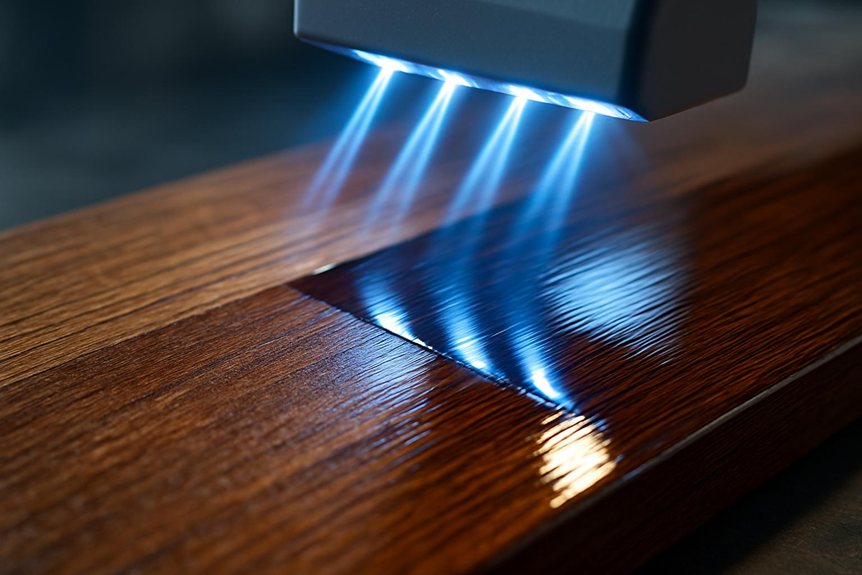

Although many finishes wear down quickly with daily use, UV-cured urethane stands out because it offers enhanced durability and scratch resistance. When you ask why choose UV cured urethane, the answer lies in its tough protective layers. Adamantine applies up to 10 layers, creating a finish that withstands scratches much better than traditional coatings. This means your surfaces stay looking new longer, even with frequent use. Plus, since the curing happens under UV light, the finish bonds tightly, preventing chips and wear. Choosing UV-cured urethane means investing in a reliable, long-lasting protection for your floors or furniture.

Superior Spill and Stain Protection

Beyond scratch resistance, UV-cured urethane offers excellent protection against spills and stains, which can damage or discolor many surfaces. When you choose this finish, liquids like wine, coffee, or oil won’t soak in or cause lasting marks. The multiple layers create a tight barrier, preventing chemicals from penetrating and reacting with the material underneath. This means you can clean up messes quickly without worrying about permanent damage. With UV-cured urethane, your surfaces stay looking fresh and new, even after accidental spills. It’s a smart choice if you want durable, easy-to-maintain protection every day.

Long-Lasting Fade Resistance

When you choose UV-cured urethane, you get a finish that stands up to the sun’s harsh effects, keeping colors vibrant for years. This durable coating creates a strong barrier against UV rays, which typically cause fading and discoloration. Because the urethane hardens instantly under UV light, it locks in pigments, preventing them from breaking down over time. This means your surfaces maintain their original look longer, even with constant sunlight exposure. So, you don’t have to worry about dull or washed-out colors, giving you peace of mind and lasting beauty in your space.

Consistent Quality With Factory Application

How can you be sure your finish will look perfect every time? When UV-cured urethane is applied in a factory setting, like with Adamantine’s process, you get unmatched consistency. The finish is built up in controlled conditions, applying up to 10 layers to guarantee even coverage. This method prevents common issues found with site-applied finishes, such as uneven coats or dust contamination. You’ll benefit from a smooth, durable surface that resists scratches and fading. By choosing factory-applied UV-cured urethane, you ensure each piece meets high-quality standards right from the start, saving you time and worry later.

Faster Curing Time Compared to Traditional Finishes

Not only does factory-applied UV-cured urethane deliver a consistent, high-quality finish, but it also speeds up the curing process significantly compared to traditional finishes. When you choose UV-cured urethane, the finish hardens almost instantly under UV light, eliminating long wait times. Traditional finishes can take hours or even days to fully dry, which slows down production and delays use. This faster curing means you can enjoy your furniture or flooring sooner without worrying about smudges or damage. Plus, quicker curing reduces the risk of dust settling on the surface, keeping your finish flawless from the start.

Environmentally Friendly UV Curing Process

Because UV-cured urethane hardens quickly under ultraviolet light, it uses less energy than traditional drying methods, making the process more environmentally friendly. You’ll appreciate that this quick curing reduces harmful emissions, as it doesn’t rely on solvents that release volatile organic compounds (VOCs). Additionally, the precise application minimizes waste, so fewer chemicals end up in the environment. By choosing UV curing, you support a cleaner production process that conserves resources and lowers your carbon footprint. This method aligns well with growing environmental standards, helping you make responsible choices without sacrificing quality or durability.

Improved Surface Smoothness and Clarity

Although many finishes can leave surfaces feeling rough or uneven, UV-cured urethane creates a remarkably smooth and clear coating that enhances the appearance of your items. This finish forms a uniform, glossy layer that highlights details and colors without distortion. Because the curing process happens instantly under UV light, it prevents imperfections like bubbles or streaks from forming. You’ll notice a flawless surface that feels pleasant to touch and looks professionally done. This clarity and smoothness aren’t just for looks—they also help protect your items by creating a strong, consistent barrier against everyday wear and tear.

Reduced Maintenance and Cleaning Effort

The smooth, clear surface created by UV-cured urethane doesn’t just look good—it makes cleaning and maintenance much easier. Because this finish resists scratches and spills, dirt and grime don’t cling to it as easily. You won’t need harsh chemicals or intense scrubbing to keep it looking fresh. Plus, the durable coating prevents stains from setting in, saving you time and effort. With less frequent cleaning required, you can focus on other tasks without worrying about wear or damage. Choosing UV-cured urethane means you get a surface that stays cleaner longer with less upkeep.

Ideal for High-Traffic and Commercial Applications

When you need a finish that can handle constant use and heavy foot traffic, UV-cured urethane stands out as an excellent choice. This finish offers exceptional durability, making it perfect for commercial spaces like offices, retail stores, and schools. Adamantine applies up to 10 layers, creating a tough surface that resists scratches, spills, and fading. Unlike traditional finishes applied on-site, UV-cured urethane ensures consistent quality every time. You’ll spend less time worrying about wear and tear, and more time focusing on your business. It’s a smart investment for any high-traffic environment needing long-lasting protection.

Frequently Asked Questions

Can UV Cured Urethane Be Applied to All Types of Wood Surfaces?

Yes, you can apply UV cured urethane to most wood surfaces. It bonds well, creating a tough, protective layer. Just ensure the wood is clean and properly prepared for the best, long-lasting finish you’ll get.

How Does UV Curing Affect the Odor During Application?

You won’t notice strong odors during UV curing because it uses rapid light activation, minimizing volatile organic compounds. This means the application is much fresher and more comfortable compared to traditional finishes with strong chemical smells.

Is UV Cured Urethane Safe for Use in Homes With Pets?

Yes, UV cured urethane is safe for homes with pets since it cures quickly, reducing harmful fumes. You’ll appreciate its durable, non-toxic finish that resists scratches and spills, keeping your pets and home protected.

What Equipment Is Required for UV Curing in a Factory Setting?

You’ll need UV lamps or LED curing units, a conveyor or curing station, and safety gear like protective eyewear. Automated systems help apply consistent layers, ensuring the urethane cures quickly and uniformly in a factory setting.

Can UV Cured Urethane Finishes Be Repaired if Damaged?

Yes, you can repair UV cured urethane finishes if they get damaged. You’ll need proper tools and techniques to carefully sand and reapply the finish, restoring its durability and appearance without compromising its protective qualities.

Conclusion

Choosing UV-cured urethane means you get durable, scratch-resistant surfaces that stay vibrant and protected against spills and stains. Its fast curing time and factory application ensure consistent quality, while the environmentally friendly process reduces energy use and emissions. This finish smooths and clarifies surfaces, making maintenance easier, especially in busy or commercial spaces. Overall, UV-cured urethane offers a smart, practical solution if you want long-lasting, low-maintenance flooring or furniture without sacrificing quality or sustainability.