When you choose a UV cured urethane coating, you want to know how well it stands up to scratches, especially in busy homes or commercial spaces. This test measures exactly that by applying controlled scratches and observing how the surface resists damage. Understanding these results helps you decide if the coating can protect your floors or furniture from daily wear and tear. But what specific factors influence the scratch resistance in these tests?

Key Takeaways

- UV cured urethane hardens quickly under ultraviolet light, providing a durable surface ideal for scratch resistance testing.

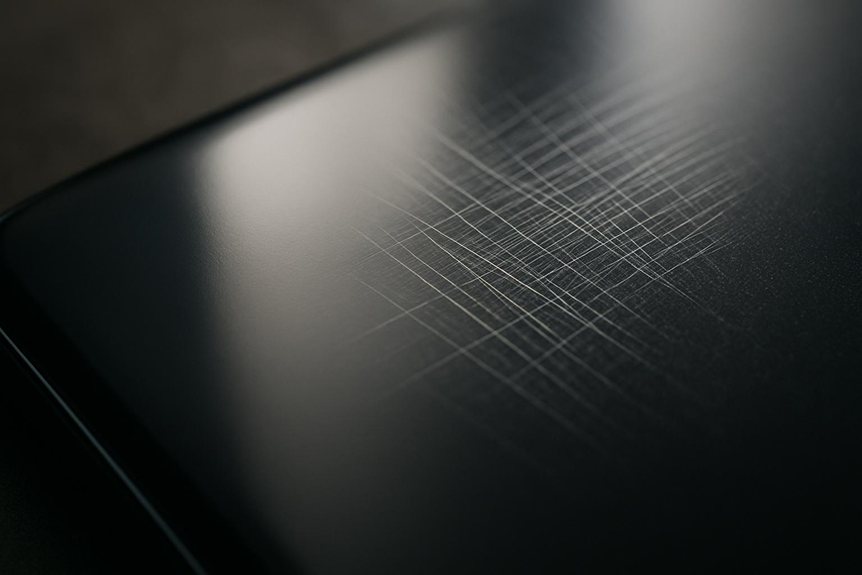

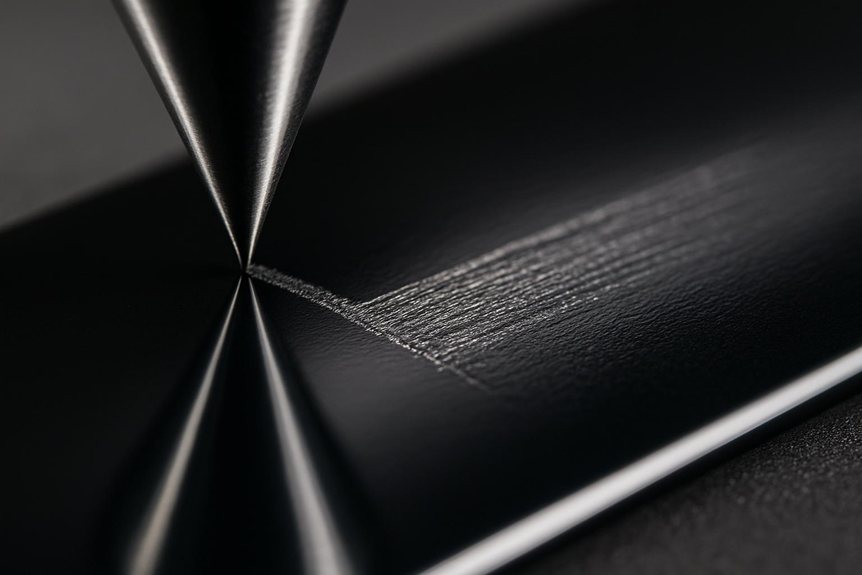

- Scratch tests use a controlled stylus or blade to evaluate the urethane’s resistance to surface damage and daily wear.

- Aluminum oxide nanoparticles in the urethane enhance hardness and improve scratch resistance by reinforcing the coating.

- Proper sample preparation and secure mounting are essential to ensure accurate and consistent scratch test results.

- Post-test examination involves microscopic inspection to assess scratch depth and surface integrity for performance evaluation.

Overview of UV Cured Urethane

Although it might seem like just another type of coating, UV cured urethane stands out because it hardens quickly when exposed to ultraviolet light. You’ll find it widely used across industries due to its durability and fast curing time. When you perform a uv cured urethane scratch test, you’re checking how well this finish resists damage from daily wear, like scrapes or scruffs. This test helps confirm its toughness, showing why it’s popular for surfaces needing strong protection. Understanding how UV cured urethane behaves under stress helps you appreciate its practical benefits in real-world applications.

Importance of Scratch Resistance

Because surfaces like flooring or furniture face constant contact and movement, scratch resistance plays a crucial role in maintaining their appearance and durability. When you choose materials that resist scratches, you protect your investment from everyday wear and tear. Scratches can quickly make surfaces look old and worn, lowering their value and appeal. By ensuring high scratch resistance, you reduce maintenance needs and keep surfaces looking new longer. This is especially important in busy homes or commercial spaces where damage happens often. So, understanding and prioritizing scratch resistance helps you select products that stand up to real-life use effectively.

Materials and Nanoparticles Used

When you look closely at UV cured urethane coatings, you’ll find that their strength and scratch resistance largely come from the materials and nanoparticles used in their formulation. You’ll often see aluminum oxide nanoparticles added because they’re incredibly hard and help the surface resist scratches from everyday wear. These tiny particles evenly disperse within the urethane, reinforcing the coating without sacrificing flexibility. Additionally, the urethane base itself provides a smooth, durable layer that cures quickly under UV light. By combining these materials thoughtfully, manufacturers create coatings tough enough to handle pet claws, furniture movement, and high foot traffic with ease.

Testing Equipment and Setup

To accurately measure the durability of UV cured urethane coatings, you’ll need specific testing equipment and a carefully arranged setup. Start with a scratch tester equipped with a controlled stylus or blade, which applies consistent force to the coated surface. Ensure the sample is securely fixed to prevent movement during testing. Lighting should be bright and even, allowing you to clearly observe scratch progression. You might also use a microscope or magnifier to inspect fine details. Calibrating the equipment before each test guarantees reliable results, helping you compare different coatings effectively. This preparation sets the foundation for precise, repeatable scratch assessments.

Laboratory Scratch Test Procedures

Although the exact steps can vary depending on the equipment used, laboratory scratch test procedures generally follow a clear sequence to ensure consistency and accuracy. You start by preparing the UV cured urethane sample, securing it firmly on the test platform. Next, you select the appropriate stylus tip and set the scratch force according to standards. Then, the machine moves the stylus across the surface at a controlled speed, creating a scratch. You carefully monitor the test, recording force and displacement data. Finally, you examine the scratch under a microscope to assess damage, ensuring reliable results for comparison.

Results From Pet Claw Simulations

Since pet claws are a common cause of floor damage, simulating their impact provides valuable insights into the durability of UV cured urethane coatings. When you test Adamantine flooring against pet claw simulations, you’ll notice it resists scratches effectively, thanks to embedded aluminum oxide nanoparticles. These tiny particles create a tough protective layer that prevents deep gouges or surface marks. You’ll find that, even under repeated stress, the coating maintains its smooth finish without visible wear. This means your floors stay looking new longer, making UV cured urethane a smart choice for pet owners concerned about claw damage.

Furniture Drag Scratch Test Outcomes

When you drag furniture across Adamantine flooring, you’ll quickly see how its UV cured urethane coating stands up to everyday wear. During testing, even heavy items caused minimal surface marks, thanks to the coating’s tough aluminum oxide nanoparticles. These particles help resist scratches from sharp edges or rough bottoms, preserving the floor’s smooth finish. You’ll notice that after multiple drags, any scuffs are superficial and easy to clean, without penetrating the protective layer. This means your flooring stays looking fresh, even with regular furniture movement, offering lasting durability and reliable scratch resistance in your home or office.

High Traffic Area Durability Tests

High traffic areas put flooring materials through some of their toughest challenges, and Adamantine flooring is no exception. When you test its durability under constant foot traffic, the UV cured urethane with aluminum oxide nanoparticles really shines. The surface resists scratches and wear, keeping its finish intact even after heavy use. You’ll notice less scuffing and fewer marks from shoes or rolling carts compared to other floors. This test simulates real-life conditions, so you can trust Adamantine’s durability in busy spaces. It’s designed to maintain appearance and strength, giving you lasting performance where it matters most.

Comparison With Traditional Flooring Materials

Although traditional flooring materials like hardwood, laminate, and vinyl have been popular choices for years, Adamantine’s UV cured urethane with aluminum oxide nanoparticles offers distinct advantages you should consider. Unlike hardwood, which can dent or scratch easily, Adamantine resists marks from pet claws and furniture. Laminate and vinyl may wear down over time, but this UV cured urethane maintains its finish even in high-traffic areas. Its aluminum oxide nanoparticles add extra durability, making it a smart choice if you want long-lasting, low-maintenance flooring. You’ll save time and money on repairs, while enjoying a surface that looks great longer.

Frequently Asked Questions

How Long Does the UV Curing Process Take for Urethane Flooring?

The UV curing process for urethane flooring typically takes just a few minutes. You’ll find it quick and efficient, letting you move on with installation or use without long waiting times.

Can UV Cured Urethane Coatings Be Applied Over Existing Floors?

Yes, you can apply UV cured urethane coatings over existing floors, but you’ll need to properly clean and prep the surface to ensure good adhesion. Make sure the floor is dry, smooth, and free of contaminants before coating.

What Environmental Conditions Affect the UV Curing Effectiveness?

You’ll want to control humidity and temperature since high moisture or extreme cold slows curing. Also, ensure proper UV light intensity and exposure time because insufficient light weakens the cure, reducing the coating’s durability and performance.

Are UV Cured Urethane Floors Safe for Allergy Sufferers?

Yes, you’ll find UV cured urethane floors safe for allergy sufferers since they resist dust and allergens well. Their smooth, sealed surface prevents trapping irritants, making your space cleaner and healthier for sensitive individuals.

How Do UV Cured Urethane Floors Respond to Chemical Spills?

You’ll find UV cured urethane floors resist chemical spills well, preventing damage and staining. Just wipe spills quickly to maintain their finish, and you won’t have to worry about long-term effects or deterioration.

Conclusion

You’ve seen how UV cured urethane coatings offer strong scratch resistance, making surfaces more durable against daily wear like pet claws and furniture movement. This test shows that these coatings protect materials better than many traditional options, extending their lifespan while keeping them looking good. Understanding the scratch resistance helps you choose the right coating for high-traffic areas, ensuring your surfaces stay resilient and maintain their appeal over time.