If you’re looking to get a quote for UV cured urethane, it helps to understand what sets this coating apart—its fast curing time and strong durability make it a popular choice. Costs can vary based on factors like formulation and application methods, so knowing your project’s specific needs is key. Before reaching out to suppliers, you’ll want to consider the details that affect price and performance, ensuring you get the best fit for your requirements.

Understanding UV Cured Urethane and Its Benefits

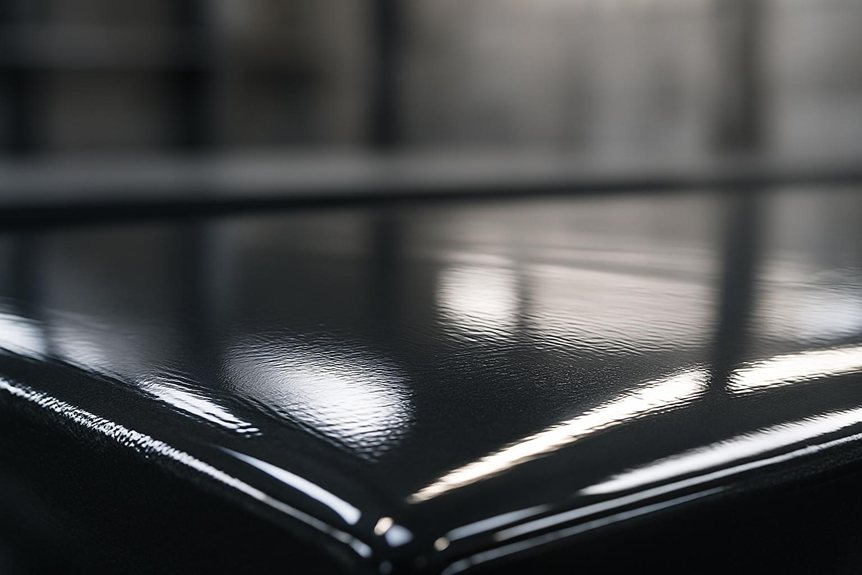

UV cured urethane is a type of finish that hardens quickly when exposed to ultraviolet light, creating a tough, protective layer on hardwood surfaces. When you get a quote for UV cured urethane, you’ll discover its key benefits: excellent scratch resistance and waterproof protection. This finish dries fast, allowing projects to complete sooner, saving you time. It also enhances the wood’s natural beauty with a clear, durable coat that lasts longer than traditional finishes. If you’re considering hardwood finishing options, don’t hesitate to get quote UV cured urethane services to ensure you get quality and value.

Factors Influencing the Cost of UV Cured Urethane

Although many people focus on the benefits of cured urethane finishes, understanding the factors that influence their cost can help you make smarter decisions for your project. The price depends on the type of urethane used, the thickness of the application, and the surface area you need to cover. Additionally, curing technology and labor costs impact the final quote. If you require extra features like enhanced scratch resistance or waterproofing, expect the price to reflect those benefits. By knowing these factors, you can better evaluate quotes and select the best option for your specific needs.

Key Specifications to Provide When Requesting a Quote

When you’re ready to request a quote for cured urethane finishes, providing clear and detailed specifications will help ensure you get an accurate estimate. You should specify the type of surface, such as hardwood, and the desired finish level, like matte or glossy. Include the total area to be coated and thickness requirements. Mention any special features you want, such as scratch resistance or waterproof protection. Also, share your project timeline and delivery location. The more precise your details, the better suppliers like Adamantine can tailor their quotes to meet your exact needs efficiently and competitively.

Comparing Competitive Quotes From Different Suppliers

How do you make sure you’re getting the best deal when comparing quotes from different suppliers? Start by looking beyond the price—check what each quote includes, like the quality of the UV cured urethane, delivery times, and any added services. Make sure the suppliers provide detailed information about scratch resistance and waterproof protection, as these affect durability. Don’t forget to consider the supplier’s reputation and customer service responsiveness. Getting multiple quotes helps you spot discrepancies and negotiate better terms. By comparing all these factors carefully, you’ll find the best value for your project without sacrificing quality or reliability.

Customizing Your UV Cured Urethane for Specific Project Needs

Since every project has unique requirements, customizing your UV cured urethane ensures you get the right balance of durability, appearance, and protection. You can adjust factors like gloss level, color tint, and thickness to match your specific needs. For example, a higher gloss finish might suit decorative flooring, while a matte option works well for less reflective surfaces. Additionally, you can enhance waterproofing or scratch resistance depending on the environment your project faces. Working closely with your supplier helps you specify these details, ensuring your UV cured urethane performs exactly as required, saving time and avoiding costly adjustments later.

How to Ensure Quality and Scratch Resistance in Your Order

Ensuring the quality and scratch resistance of your UV cured urethane starts with knowing exactly what to look for and how to communicate your expectations clearly. You should ask about the specific hardness rating and whether the finish includes additives for extra durability. Request samples or test results to verify scratch resistance and waterproof properties. Be clear about your project’s demands, so the supplier can recommend the best formulation. Also, confirm the curing process used, since proper UV curing affects the coating’s strength. Taking these steps helps you get a product that holds up well in daily use.

Steps to Finalize and Approve Your UV Cured Urethane Quote

After confirming the quality and scratch resistance of your UV cured urethane, the next step is to finalize and approve your quote. Review all details carefully, including pricing, delivery timelines, and product specifications. Don’t hesitate to ask questions if anything seems unclear or if you need adjustments. Once you’re confident everything matches your project’s needs, give your formal approval to proceed. This ensures the supplier understands your expectations and can start production promptly. Remember, clear communication here helps avoid delays or surprises later, making the entire process smooth and efficient for your UV cured urethane order.

Frequently Asked Questions

What Is the Typical Lead Time for UV Cured Urethane Delivery?

You can typically expect UV cured urethane delivery within 1 to 3 weeks, depending on order size and customization. Don’t hesitate to contact the supplier directly—they’ll provide a precise lead time tailored to your project.

Are There Environmental Certifications for Your UV Cured Urethane?

Yes, our UV-cured urethane carries environmental certifications ensuring it’s eco-friendly and low in VOCs. You’ll feel confident choosing a product that supports sustainability while delivering excellent durability and protection for your hardwood project.

Can UV Cured Urethane Be Applied to Non-Wood Surfaces?

Yes, you can apply UV cured urethane to non-wood surfaces like plastics and metals. Just make sure the surface is properly prepared for optimal adhesion and durability, so your project achieves the best scratch resistance and waterproofing.

What Maintenance Is Required After Applying UV Cured Urethane?

You won’t need much maintenance after applying UV-cured urethane; just clean surfaces with a soft cloth and mild soap. Avoid harsh chemicals or abrasive tools to keep that scratch-resistant, waterproof finish looking great for years.

Are There Bulk Order Discounts for UV Cured Urethane?

Yes, you can get bulk order discounts for UV cured urethane. Just reach out to Adamantine with your project details, and they’ll provide a competitive quote tailored to your quantity and specific needs.

Conclusion

Now that you understand the benefits and key factors of UV cured urethane, you’re better equipped to request an accurate quote. By providing clear specifications and comparing offers from different suppliers, you can find the best fit for your project. Remember to customize your order to meet quality and scratch resistance needs, and follow the proper steps to finalize your quote. This approach ensures you get a reliable product that performs well and fits your budget.